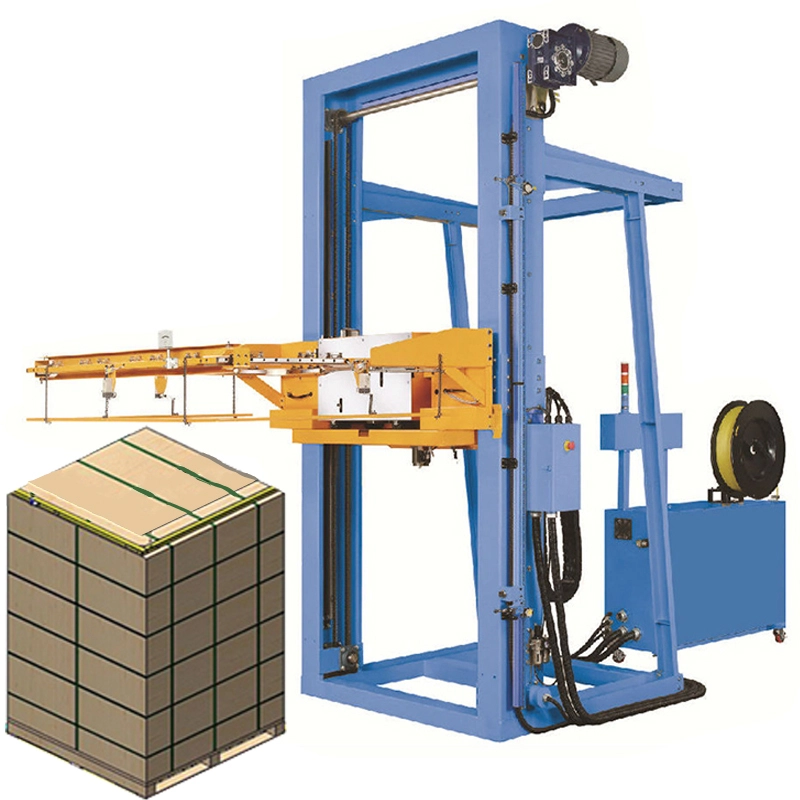

Automatic Top-seal Horizontal Pallet Strapping Plastic Machine

This automatic top-seal horizontal pallet strapping plastic machine is designed to efficiently and securely strap pallets for transportation and storage. With its automatic top-seal feature, it provides added protection and stability for a wide range of pallet sizes, making it a valuable addition to any industrial packaging operation.

The dimensions of this automatic top-seal horizontal pallet strapping plastic machine are designed to accommodate standard pallet sizes, providing a versatile and adaptable solution for strapping and securing goods for shipping and storage.

Product details

Production Workshop

It boasts 3 subsidiaries and 2 production facilities in the Packaging zone of Jinan city and High tech zone of Jining city.

Product description

● The interior is organized in an orderly manner,controlled by multiple inverters, and the machine runs quickly and accurately. Equipped with electricity protection device electricity safety.

● Both the strapping motor and the conveying motor adopt high-quality motors to ensure the running power of the machine and ensure that the machine can run for a long time.

● Fast melting speed up the strapping speed, The melting temperature is adjustable, suitable for different straps.

Technology Data

|

Electrical

|

380V/50Hz

|

|

Power consumption

|

3.1KW/5A

|

|

Air compress

|

0.4-0.6Mpa

|

|

Strapping speed

|

15s/strap

|

|

Strapping strength

|

0-90kg adjustable

|

|

Strapping type

|

One strap or some strap

|

|

Strapping method

|

Point move or automatic control move

|

|

Arch

|

Iron arch

|

|

Arch size

|

W1500mm×H1500mm(can customized)

|

|

Working table height

|

customized

|

|

Strap width

|

Width 13-15mm thickness 0.55-1.0mm(0.1)

|

|

Strap roll size

|

Width:160-180mm

inner dia. 200-210mm

Outer dia. 400-500mm

|

|

Stick method

|

Hot melt, side stick, stick space ≥90%,stick place tolerance ≤2mm

|

|

Machine size

|

L1930mm×W3240mm×H2800mm

|

|

Machine weight

|

350kg

|