Heavy Duty Automatic Pallet Wrapping Machine for Industrial Packaging

Product details

Our automatic pallet wrapping machine is built to handle the toughest packaging challenges in warehouses and distribution centers. The heavy-duty steel frame supports continuous operation, while the user-friendly control panel allows easy adjustment of wrapping parameters. Features include programmable wrap cycles, adjustable tension control, and optional top sheeting for complete load protection. The machine's motorized film carriage ensures smooth, consistent wrapping every time for pallets up to 6 feet tall.

Product display

The Myway pallet wrapping machine offers significant benefits over manual wrapping or inferior machines. Our advanced pre-stretch system reduces film consumption by up to 50%, cutting packaging costs substantially. The fully automated operation eliminates labor-intensive manual wrapping, allowing one operator to package multiple pallets simultaneously. Specialized features include built-in overload protection, emergency stop functions, and the ability to wrap irregular-shaped loads securely. Unlike competitors' models, our machine can handle weights up to 3,000 kg without compromising wrapping quality. The low maintenance design requires minimal servicing while delivering years of reliable performance in harsh industrial environments.

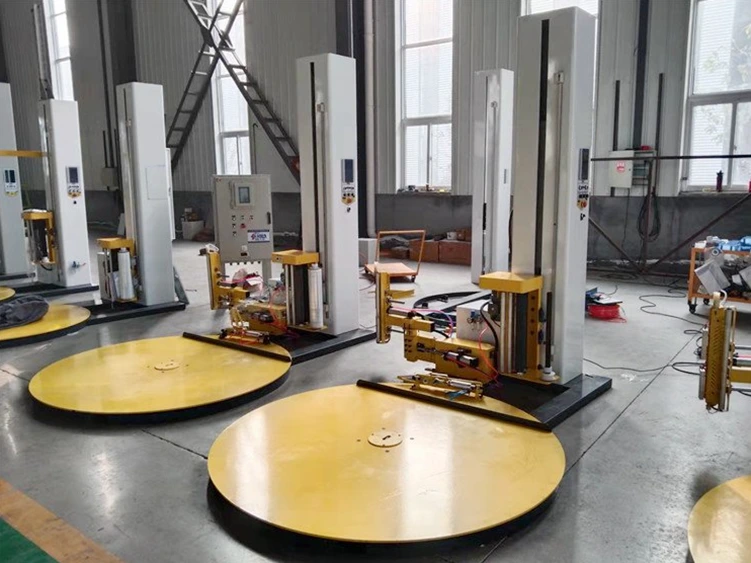

Production Workshop

As a professional manufacturer with over 10 years of experience, Myway operates five dedicated production lines for packaging equipment. Our 15,000 square meter facility in China houses state-of-the-art CNC machining centers and a team of 50 skilled technicians. Every pallet wrapping machine undergoes rigorous quality control checks at multiple production stages, including material inspection, assembly verification, and 72-hour operational testing. We hold ISO 9001 certification and our machines meet CE, UL, and other international safety standards. With successful exports to North America, Japan, and Singapore, we've built a reputation for quality machines with industry-leading 24-month warranties. Our engineering team can customize machines to specific voltage requirements, throughput needs, and special packaging applications.

Technology Data

|

Model |

T1650F |

|

Wrapping product size |

L(500-1200) mm × W(500-1200)mm |

|

Wrapping height |

L type: 1800mm H type: 2400mm Y type: 2800mm |

|

Packing efficiency |

20-40 pallet/h |

|

Rotary speed |

0~15rpm rotary speed, adjustable, steady start and stop |

|

Turntable size |

Dia:1650mm Height:78mm |

|

Turntable weight capacity |

2000kgs |

|

Film carriage system |

Pre-stretch film carriage, pre-stretch up to 250%,automatic transport film |

|

Up and down upright |

Double chain structure, adjustable up and down speed by transducer |

|

Control system |

PLC programmable |

|

Power |

Turntable 0.75kw, film carriage 0.4kw, upright 0.37kw |

|

Machine weight |

700kg |

|

Machine size |

2745mm×1650mm × (2260-3260) mm |

FAQ

Q1: How do I choose between semi-automatic and fully automatic pallet wrapping machines?

A: For operations wrapping under 50 pallets daily, our semi-automatic model offers excellent value with manual film attachment. For higher volume facilities processing 100+ pallets per shift, the fully automatic version increases productivity with automatic film cutting and clamping. We'll analyze your specific needs to recommend the ideal solution.

Q2: What maintenance does the machine require to ensure long service life?

A: Our machines are designed for minimal maintenance - just monthly chain lubrication and occasional film carriage roller cleaning. Critical components use sealed bearings that don't require regular servicing. We provide detailed maintenance manuals and video guides with every purchase.

Q3: Can your machine handle oddly shaped loads or unstable pallets?

A: Absolutely. Our proprietary stabilization system accommodates irregular loads through adjustable containment force settings. Optional stabilizing arms are available for particularly challenging loads where standard wrapping might be insufficient.

Q4: How does your shipping and installation process work for international buyers?

A: We ship machines fully assembled in secure wooden crates with all necessary documentation. For international orders, we handle customs clearance and arrange door-to-door delivery. Installation is straightforward - our technicians provide remote video support, and we can dispatch local engineers if needed for complex setups.

Q5: What payment terms do you offer for first-time buyers?

A: New clients typically use 30% deposit with balance before shipment via T/T. For orders over $50,000, we can discuss flexible payment plans. All transactions are processed securely through our corporate bank accounts with complete transparency.