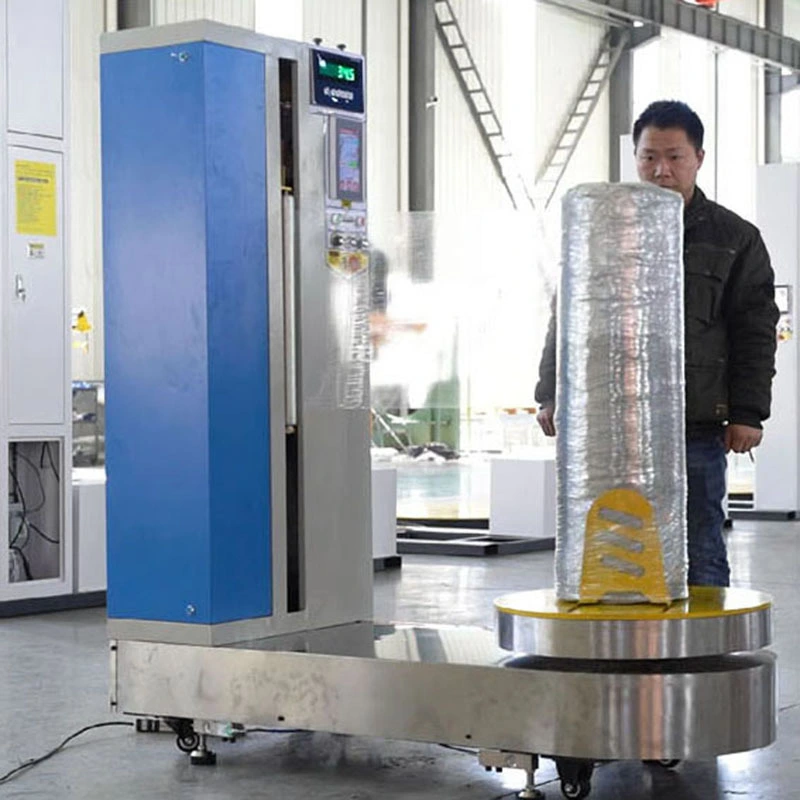

Heavy-Duty Luggage Wrapping Machine for Airports and Hotels

Product details

Engineered specifically for airport and hotel environments, our wrapping machine outperforms standard models with professional-grade components throughout. The advanced pre-stretch technology saves up to 30% on film costs while maintaining superior load containment. Dual safety sensors automatically detect irregular shapes and adjust wrapping parameters accordingly, virtually eliminating film breaks or jams. Heavy-duty construction uses powder-coated steel frames that resist corrosion even in humid environments. Specialized rubberized rollers ensure smooth film feed without tearing, while the integrated tension control maintains consistent pressure regardless of luggage weight or shape. Energy-saving motors reduce power consumption by 40% compared to conventional machines, with automatic standby mode cutting electricity use during idle periods. The intuitive LCD touchscreen displays wrapping counts, film usage statistics and maintenance alerts in real time. Custom branding options allow businesses to imprint logos or contact information directly onto the wrapped film - excellent for lost and found identification.

Product description

Advantages & Features:

Speed Boost: Wraps 240 bags/hour, cutting labor costs by 50%.Heavy-Duty Build: Stainless steel frame handles 150kg loads daily.Custom Controls: Adjust film tension, rotation speed, and height via touchscreen.Safety First: Infrared sensors halt operation if obstructions are detected.Low Upkeep: Sealed motors resist dust and require minimal maintenance.

Quality motor

● Ariable speed, stable operation, strong power and long service life.

Turntable

● Automatic tightening, strong clamping force, goods do not fall.

Film carriage membrane rack system

● Pre stretched waist frame, pre stretched up to 250%, daily film deeding, frequency conversion speed.

Retrofitting simple operation

● Camera, weighing device and counting device can be added.

Production Workshop

At our 50,000 sq ft specialized facility in Guangzhou, we manufacture wrapping machines that meet the toughest industry demands. Each machine begins with aerospace-grade aluminum frames that undergo stress testing far exceeding normal operational requirements. Our production line features robotic welding stations that ensure perfect seams on all structural components. Skilled assemblers hand-fit each gearbox and roller assembly, then test for smooth operation before installation. Before shipping, every unit completes a rigorous 100-hour burn-in test simulating real-world conditions, including wrapping various luggage sizes continuously with performance monitoring. The facility maintains ISO 9001 certification with additional CE, UL and RoHS compliance for international markets. Our engineering team works directly with major airport operators worldwide to incorporate real-user feedback into continuous design improvements. With dedicated production lines for different machine models, we maintain the flexibility to accommodate special requests while keeping lead times under 3 weeks for standard configurations.

Technology Data

|

Model |

LP600 |

|

Shape Dimensions(mm) |

1570(L) ×650(W) ×1200(H) |

|

Load size(mm) |

180-350(W) ×400-800(L) ×300-450(H) |

|

Power supply |

220V/50HZ/1 Phase 0.5 Kw |

|

Weight Capacity |

100 Kg |

|

Packing materials |

Stretch film width: 500mm |

|

Machine Weight |

200 Kg |

FAQ:

What's the typical lifespan of these machines?

With proper maintenance, our luggage wrappers typically last 8-10 years in commercial airport environments wrapping 300+ bags daily. The motors and gearboxes are rated for 50,000 operating hours. We've had machines in continuous service at major Asian airports since 2015 still performing flawlessly with only routine part replacements.

Can you supply replacement parts quickly?

We stock all critical replacement components at warehouses in Los Angeles, Frankfurt and Singapore for next-day dispatch. Common wear items like rollers and cutters are kept in inventory at our Guangzhou factory ready for immediate shipment. Each machine ships with a detailed parts manual showing exploded diagrams for easy identification.

How does your machine handle fragile items?

The adjustable tension system lets operators select gentle wrapping modes for delicate contents. The machine automatically reduces rotational speed when sensors detect lightweight luggage, preventing excessive compression. We also offer optional padded rollers that cradle fragile items during wrapping - particularly useful for musical instruments or sports equipment.

Do you offer financing or lease options?

Yes, we work with several international trade finance companies that provide competitive lease-purchase plans starting at 36 months. Many of our hotel chain customers prefer this option as it converts capital expenditure into operational costs. Our sales team can provide tailored financial solutions based on your purchase volume and location.